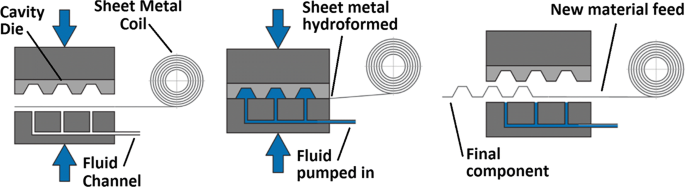

2002 and also thiruvarudchelvan and lewis 1999 noted in their work for types of sheet metal hydroforming process including hydrostatic deep drawing hydrodynamic deep drawing single sheet forming at high internal pressure single sheet hydroforming and forming a pair of.

Hydroforming of sheet metal pairs.

Hydroforming of sheet metal pairs.

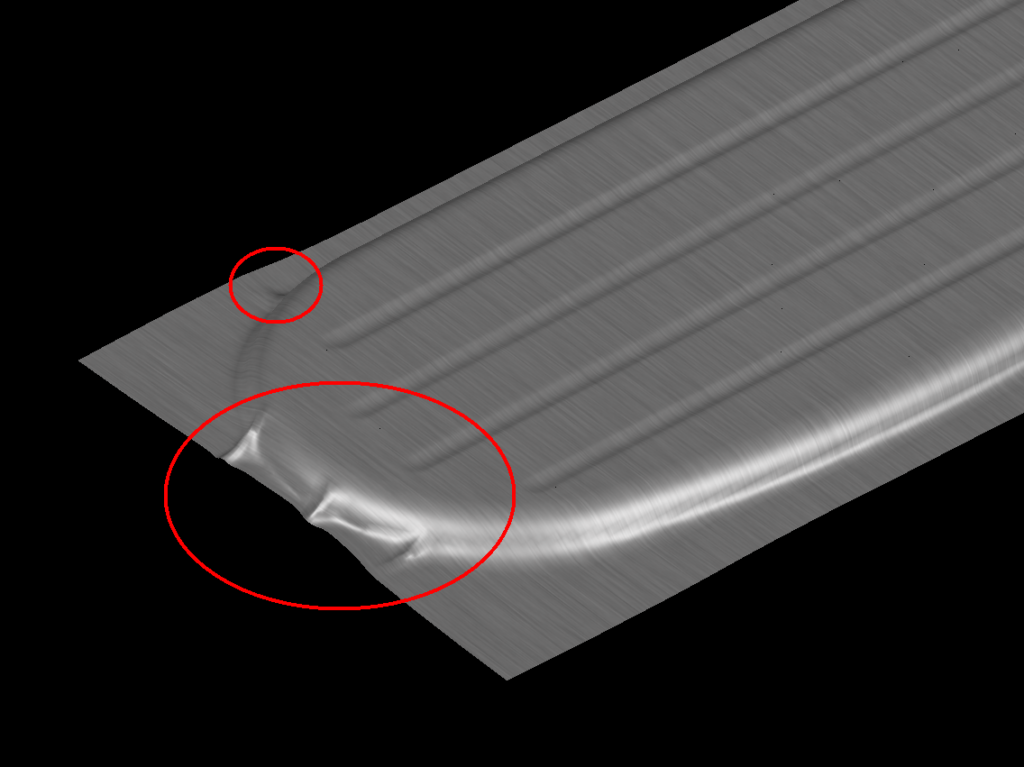

At the chair of manufacturing technology research on the hydroforming of sheet metal pairs was done in the last years using the deep drawing steel sheet dc04 with a material thickness of 1 5 mm.

Hydroforming of sheet metal pairs is a new field of investigation for manufacturing engineering.

Hydroforming is a way of shaping metals such as aluminium low alloy steel brass and stainless steel into structurally solid and strong light weighted pieces.

Numerical simulations as well as analytical models have illustrated the need for proper load path control and for defined friction conditions in order to achieve optimal mechanical properties and geometric accuracy.

Micro mesoscale metal sheet hydroforming shf process is an efficient approach suitable for mass production to fabricate metal parts with micro mesochannel features.

Especially the oil pan is a difficult part to manufacture without defects by the conventional forming process.

Procedure and device for manufacturing printed parts with very smooth cutting surface and increased functional surface.

Hydroforming is commonly used within the automotive and aerospace industry where complex shapes by hydroforming can be produced stronger lighter and more solid.

These two parts are known to have geometrical constraint in each corner.

In order to improve.

We provide hydroforming solutions that quite literally stamp out all the drawbacks associated with the metal stamping process.

The hydroforming process of a sheet metal pair is treated for manufacturing of two kinds of parts.

In conventional sheet hydroforming process the channel s feature sizes e g the channel width fillet radius etc are much greater than the sheet s thickness so that the.

An oil pan shape and a rectangular cup.

Hydroforming of sheet metals has four major types as shin et al.

26 and industrial examples of hydroformed metal pairs b 3132 a special case of sheet hydroforming is the hydroforming of welded closing sheet metal pairs figure 9a shows the scheme of the.

They are characterised by the use of sheet metal pairs thus allowing an extended variety of shapes but they require special sealing and docking devices.

While metal stamping has been the conventional method of choice for metal forming there is little doubt today that hydroforming is the definitive future of metal forming.