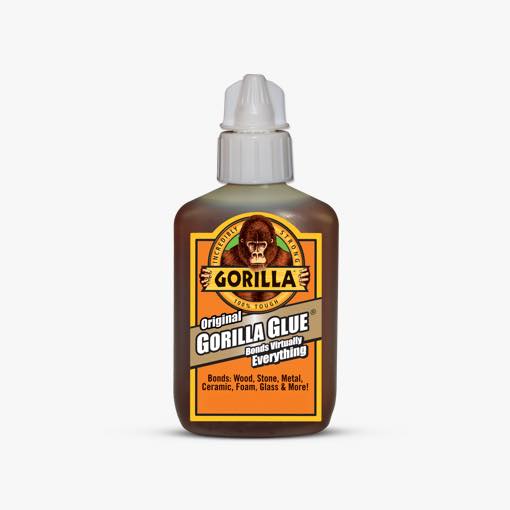

Gorilla glue is a polyurethane based indoor outdoor glue that claims to be incredibly strong and to bond to almost any surface including wood metal and more.

Is gorrila glue good for sheet metal patch panel.

Gorilla construction adhesive gorilla construction adhesive is a tough versatile and water resistant formula that instantly grabs surfaces offers superior strength and bonds virtually any surface including wood drywall concrete paneling trim molding ceramic tile and more.

Everyone who works with metal from metal workers and mechanics to jewelers and hobbyists knows gluing metal needs good preparation.

Posted december 18 2013 have heard that it is possible to put patch panels on with adhesive but after a time the seam will show through the paint.

Gorilla glue is primarily used to bind metal wood and other materials which are hard to stick.

Notice the heavy bead 1 4 inch of adhesive along the entire bare metal contact.

Its most highlighted feature is that it doesn t lose its quality in hot and cold weather.

Thankfully diy blog design sponge has put.

Finding the right glue for the job isn 39 t always an easy task and if you get it wrong your diy project will fall apart before you even get started.

Consequently there are many use cases for polycarbonate such as a replacement for security windows or tiny non conductive parts continue reading.

For most everyday situations and simple diy projects a liquid adhesive or glue for metal is the best solution.

Perfect for instantly repairing emergency leaks the rubberised uv resistant backing can be flexed and stretched before application to adapt to your surfaces.

Polycarbonate is a modern plastic material with many beneficial properties namely its high optical clarity and great durability.

Learn how customers rating this product.

Metal glue is a great way to join metal to metal or metal to other materials.

As there are no ready made patch panels or skins for the mighty montero i fabbed up some one off templates with a sharpie poster board and protractor for angle measurements.

I then used the templates to trace out the patch panels on some sheet metal.

I thanked my lucky stars i was working with boxy squared off 80s suv design.

This makes it tough to get removed once it gets old.

Once the extra strong tape has bonded it stays that way.

Right after the panels got the glue they were quickly aligned and clamped together before the adhesive set up.